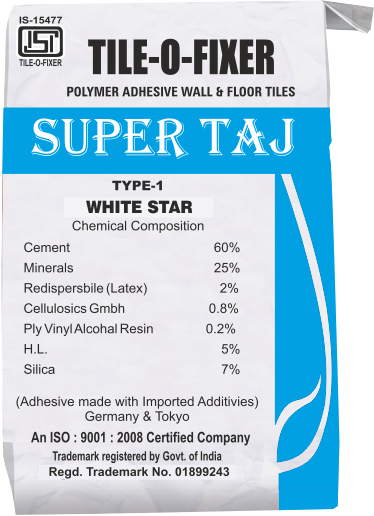

SUPER TAJ SHREE

White STAR (ST-225)

Polymer modified tile adhesive

DESCRIPTION

Polymer modified grey & white cement-based adhesive, suitable for fixing ceramic tiles for floors & walls in interior situations. Suitable for fixing ceramic tiles upto 6 mm bed thickness (can be extended up to 12 mm thickness in area of limited extent). The set adhesive is water-resistant and is suitable for use in showers and bathrooms.

Note: Not recommended for direct use onto gypsum plaster (wall finishes), paint or metal

STANDARDS

Complies with IS 15477: 2019 Type 1T “Adhesives for use

with Ceramic on the floor”.

FEATURES:

- Polymer modified adhesive

- Good bond strength

- Easy mixing & application

- Water resistant

- Enhanced flexibility & adhesion can be obtained with addition of ADMIX AD1 (latex additive).

SUITABLE SUBSTRATES

- Brick work/ Concrete

- Cement sand screed

- Sand/ Cement Rendering

PHYSICAL PROPERTIES

| Bed Thickness | upto 6 mm (suitable upto 12mm in areas of limited extent) |

| Pot Life | 3 hours |

| Setting Time | 24 hours |

| Temperature Resistance | -5°C to 50°C |

| VOC Content | 0.84 g/L |

| Heavy Traffic | 16 to 24 hours |

| Property with Test Method | Min. Requirements | Typical Result |

|---|---|---|

| Tensile Adhesion Strength (as per Annex A) Dry condition | 0.50 N/mm² | >0.90 N/mm² |

| Shear Adhesion Strength (as per Annex B) Dry condition | 1.00 N/mm² | >1.00 N/mm² |

| Open time (as per Annex C) | As per Mftr. | 20 mins |

| Adjustment time (as per Annex D) | As per Mftr. | 15 mins |

| Slip (as per annex E) | < 0.50 mm | 0.22 mm |

COVERAGE ESTIMATES

Pack size 20 kg

| Notch Trowel size | Consumption/m² (@ 45° angle of trowel) |

|---|---|

| 6mm X 6mm | |

| 8mm X 8mm | |

| 12mm X 12mm |

Coverage:

Approx. 35-40 sft per 20kg bag with 1/4” x1/4”

(6mmx6mm) square notched trowel for average

Bed of 3mm.

Coverage will vary depending on trowel notch size,type and

Size of tile and substrate smoothness and evenness.

APPLICATION INSTRUCTIONS:

Substrate Preparation

Before starting any work ensure that the base is:

Sufficiently flat to permit the specified flatness of finished tiling, bearing in mind the permissible thickness of the adhesive.

Suitable for tiling in the service conditions to which it will be exposed.

Surfaces to be tiled must be dry, clean and free from loose material and contamination.

SITE WORK INSTRUCTIONS

Surface considerations

New Cement Sand rendering/Brick/Block Wall: Before commencing tiling, allow plastered surface to air dry for atleast 2 weeks.

New Concrete Bases: Before commencing tiling, ensure that bases have been allowed to air dry for at least 4 weeks

Mixing

Add White STAR to clean water. Mix thoroughly until a lump-free mortar is obtained. A 20 kg bag will require approx. 3.55 – 3.65 litres of water to obtain a slump-free consistency. The adhesive is immediately ready-for-use and has a pot life of 3 hours. No further water should be added. Where mixing by weight is not possible, volume mixing can be carried out at site in the ratio of 1 : 3 (water : powder)

APPLICATION

1. Spread not more than the area which can be tiled within the open time of the adhesive.

2. The mixed adhesive is applied to the prepared surface with a trowel and then combed through with a suitably sized square toothed notched trowel.

3. The tiles should be fixed within the open time of the adhesive and pressed into place with a twisting and sliding action ensuring solid bed fixing is achieved. The open time is dependent on site conditions and will be extended in lower temperatures and shortened at higher temperatures.

4. Check periodically that good contact is maintained with the back of each tile.

5. Touch the adhesive ribs periodically and if a skin has formed,remove the adhesive and apply a new layer.

6. Leave adequate joints between individual wall and floor tiles unless self-spacing tiles are used.

7. Clean off surplus adhesive from the tile face and between joints

Note:

1. Spread not more than the area which can be tiled within the open time of the adhesive.

2. The mixed adhesive is applied to the prepared surface with a trowel and then combed through with a suitably sized square toothed notched trowel.

3. The tiles should be fixed within the open time of the adhesive and pressed into place with a twisting and sliding action ensuring solid bed fixing is achieved. The open time is dependent on site conditions and will be extended in lower temperatures and shortened at higher temperatures.

4. Check periodically that good contact is maintained with the back of each tile.

5. Touch the adhesive ribs periodically and if a skin has formed, remove the adhesive and apply a new layer.

6. Leave adequate joints between individual wall and floor tiles unless self-spacing tiles are used.

7. Clean off surplus adhesive from the tile face and between

joints

SPACERS

Use supertaj spacers for uniform joint width.

GROUTING

Grouting should be carried out after 24 hours of tiling. Use the appropriate grouting material from the range of cementitious and epoxy grouts.

Note: The addition of ADMIX GT1 to cement – based grouts will enhance adhesion to tile edges, increase water resistance and improves flexibility.

CLEANING

Tools and containers may be cleaned using clean water when the adhesive is still fresh. The hardened adhesive can be removed from tools mechanically

STORAGE AND SHELF LIFE

White STAR has a shelf life of 12 months when stored in normal dry conditions.

PRECAUTIONS

Keep out of reach of children. Wear suitable protective clothing, gloves and eyes/face protection. After contact with skin, wash immediately with plenty of clean water. In case of contact with eyes rinse immediately with plenty of clean water and seek medical advice. For more details please refer the relevant Material Safety Data Sheet

CONDITIONS OF SALE

Sold subject to the Company’s conditions of sale which are available on request.

NOTE

The information supplied in this datasheet is based upon extensive experience and is given in good faith in order to help you. Our Company policy is one of continuous Research and Development; we therefore reserve the right to update this information at any time without prior notice. We also guarantee the consistent high quality of our products; however as we have no control over site conditions or the execution of the work, we accept no liability for any loss or damage which may arise as a result thereof.