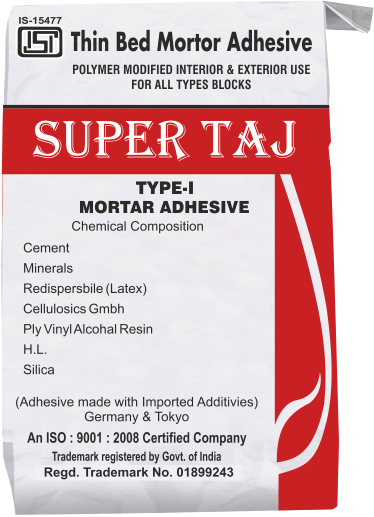

SUPER TAJ SHREE

AAC Block Adhesive

DESCRIPTION

Polymer based thin-set adhesive for laying and construction with AAC Blocks and other light weight masonry units

Substrates

- AAC Blocks

- Cement Mortar Blocks/Bricks

- Concrete hollow blocks

- Light weight masonry blocks

- Cellular concrete blocks

- Fly Ash Bricks

- Calcium silicate bricks

- Clay Bricks

Features / Benefits

- Improved bond strength

- No curing required after block work is done

- Flexible, shock & impact resistant

- Optimum compressive & splitting tensile strength

- Easy to use

- Long working time

- Fast & economical

Application

For interior and exterior use for construction with thin bed

mortar for AAC, ALC and cellular concrete blocks.

TECHNICAL DATA

Performance Properties:AAC Block Adhesive mixed with Water

Performance Properties:

ANSI A 118.1T, ASTM C 1660, ASTM C 270, IS 2250 & EN 12004 / ISO13007 (Class C1T)

| ANSI Data | ||

|---|---|---|

| Property : Test method | Requirement | Typical Values |

| Open Time (20 Minutes at 28 days): ANSI A118.1 Clause – 5.3 | ≥75 psi (0.50 Mpa) | 95 psi – 100 psi (0.65 – 0.69 Mpa) |

| Sag: ANSI A118.1- Clause 6.0 | ≤0.02 Inches (0.50 mm) | 0.016 – 0.018 Inches (0.40-0.45 mm) |

| Glazed wall tile Shear Strength | ||

| 7 Days: ANSI A118.1 – Clause 7.1.2 | >200psi (1.38Mpa) | 200-225 psi (1.38 Mpa-1.55 Mpa) |

| 7 Days Water immersion: ANSI A118.1- Clause 7.1.3) | >150psi (1.03Mpa) | 150-175 psi (1.03 Mpa-1.20 Mpa) |

| Porcelain Mosaic Tile Shear Strength | ||

| 1 Day: ANSI A118.1 – Clause 7.2.2 | >50psi (0.34Mpa) | 50 -75 psi (0.34 Mpa-0.51 Mpa) |

| 7 Days: ANSI A118.1 – Clause 7.2.3 | >150psi (1.03Mpa) | 150-175 psi (1.03 Mpa-1.20 Mpa) |

| 7 Days Water immersion: ANSI A118.1 – Clause 7.2.4 | >100psi (0.69Mpa) | 125-150 psi (0.86 Mpa-1.03 Mpa) |

| 28 Days: ANSI A118.1 – Clause 7.2.5 | >150psi (1.03Mpa) | 150-175 psi (1.03 Mpa-1.20 Mpa) |

| 12 Weeks: ANSI A118.1 – Clause 7.2.6 | >150psi (1.03Mpa) | 150-175 psi (1.03 Mpa-1.20 Mpa) |

The adhesive mortar conforms to ANSI A 118.1T

| ASTM C 1660 Data | ||

|---|---|---|

| Property: Test Method | Requirement | Typical Values |

| Splitting Tensile Strength: Test Method ASTM C1660 | 58 -71 psi (0.40 – 0.49 MPa) | 50 – 70 ps |

The adhesive mortar conforms to ASTM C 1660

| Property : Test method | Requirement | Typical Values |

| Compressive Strength : ASTM C109 | Minimum 750 psi (5.2Mpa) | 850-950 psi |

| Water Retention: ASTM C1506 | Minimum 75% | 85%-90% |

| Air Content : ASTM C91 | Maximum 14% | 10%-12% |

| Property : Test method | Requirement | Typical Values |

| Compressive Strength : ASTM C109 | Minimum 750 psi (5.2Mpa) | 850-950 psi |

| Water Retention: ASTM C1506 | Minimum 75% | 85%-90% |

| Air Content : ASTM C91 | Maximum 14% | 10%-12% |

The adhesive mortar conforms to ASTM C 2250

Specifications subject to change without notification.

Results shown are typical but reflect test procedures used.

Actual field performance will depend on installation

methods and site conditions.

Packaging: 20 kg

Colour: Grey

Coverage:

The following is the coverage table for wall area in Square feet that can be constructed using AAC Blocks of size 600mm X 200mm X 100mm

| ASTM C 2250 Data | ||

|---|---|---|

| Property: Test Method | Requirement | Typical Values |

| Compressive Strength: Appendix A | 130-150 mm | 135-145 mm |

| Water Retention: Appendix C | Minimum 70% | 85%-90% |

Coverage is based on smoothness and evenness of the substrate, size of blocks used and the thickness of mortar used. A general guide line for coverage of mortar is given when used with 30% Water is added to powder.

Working Properties at 70° F (21° C)

AAC Block Adhesive mixed with Water

| Adjustability time | 20 minutes |

| Pot Life | 2 Hours |

INSTALLATION

Surface Preparation:

All surfaces should be between 40 F (4 C) and 90 F (32 C) and structurally sound, clean and free of all dirt, oil, grease, concrete sealers or curing compounds. Rough or uneven concrete surfaces should be made smooth with MYK LATICRETE Latex Portland Cement underlayment to provide a wood float (or better) finish. Installation may be made on a damp surface.

All labs must be plumb and true to within ¼” (6mm) in 10 ft (3m).

Follow ANSI Specification AN 3.8 “Requirements for Expansion Joints” or TCA Detail EJ171 “Expansion Joints”. Do not cover expansion joints with mortar.

NOTE: In order to realize all the product advantages, for high quality construction and best performance, it is necessary to follow the AAC Block Manufacturer’s instructions or IS 6041 or other relevant codes and good practices.

Mixing:

Use approx. 50kg of AAC Block Adhesive thin bed mortar with Approx. 15 ltrs of potable water. Take water in the container and slowly add the powder into the water while mixing by hand or slow speed mixing machine. Mix for 3 to 5 minutes till a smooth thixotropic mix without lumps is obtained.

APPLICATION:

1) Thin bed mortar for laying blocks: Before placing mortar, ensure the block work to be dry and surfaces cleaned properly. Place the mixed mortar on the block work in thin layers of 2 to 3 mm (or as required by engineers at site) using trowel and place the next layer of blocks on the mortar. Keep joints between the blocks as required by the site engineers and fill the joints with the mixed mortar, using a trowel. Check the plumb of the wall while laying the blocks to keep the walls perfectly vertical to the plumb.

2) As Adhesive to install tiles: AAC Block Adhesive can be used as a thin-set adhesive to install tiles/stones on masonry walls. Use a suitable notch trowel to achieve desired thickness of adhesive for installation of tiles /stones on the wall.

Plaster:

Plumb, square and true concrete block wall can be finished with the applications of Special polymer plaster from MYK Laticrete.

Plasters made with site mix may slump and powder due to water absorption of the block work.

CLEANING:

Clean tools and containers with water while mortar is fresh.

CUSTOMER CARE

PANKAJ PETROCHEM PVT LTD

VPO BAHU AKBARPUR, MOKHRA LINK ROAD

ROHTAK– 124001

Customer Care No: 8221925838

Website: www.supertajshree.com